For us, tradition means not losing sight of quality and, above all, craftsmanship, despite industrial production. It is precisely this point that contributes greatly to the safety and value of our products.

When you have been developing and building kilns since 1950, tradition becomes an obligation. We have gained our experience primarily in the construction of kilns for industry and ceramists, who place the highest demands on quality and functionality. It is precisely in these areas that kilns are put to the test – often in continuous operation for days on end.

In addition to new kilns, we also offer spare parts for older models from the EFCO and UHLIG product ranges. All our products are made in Germany.

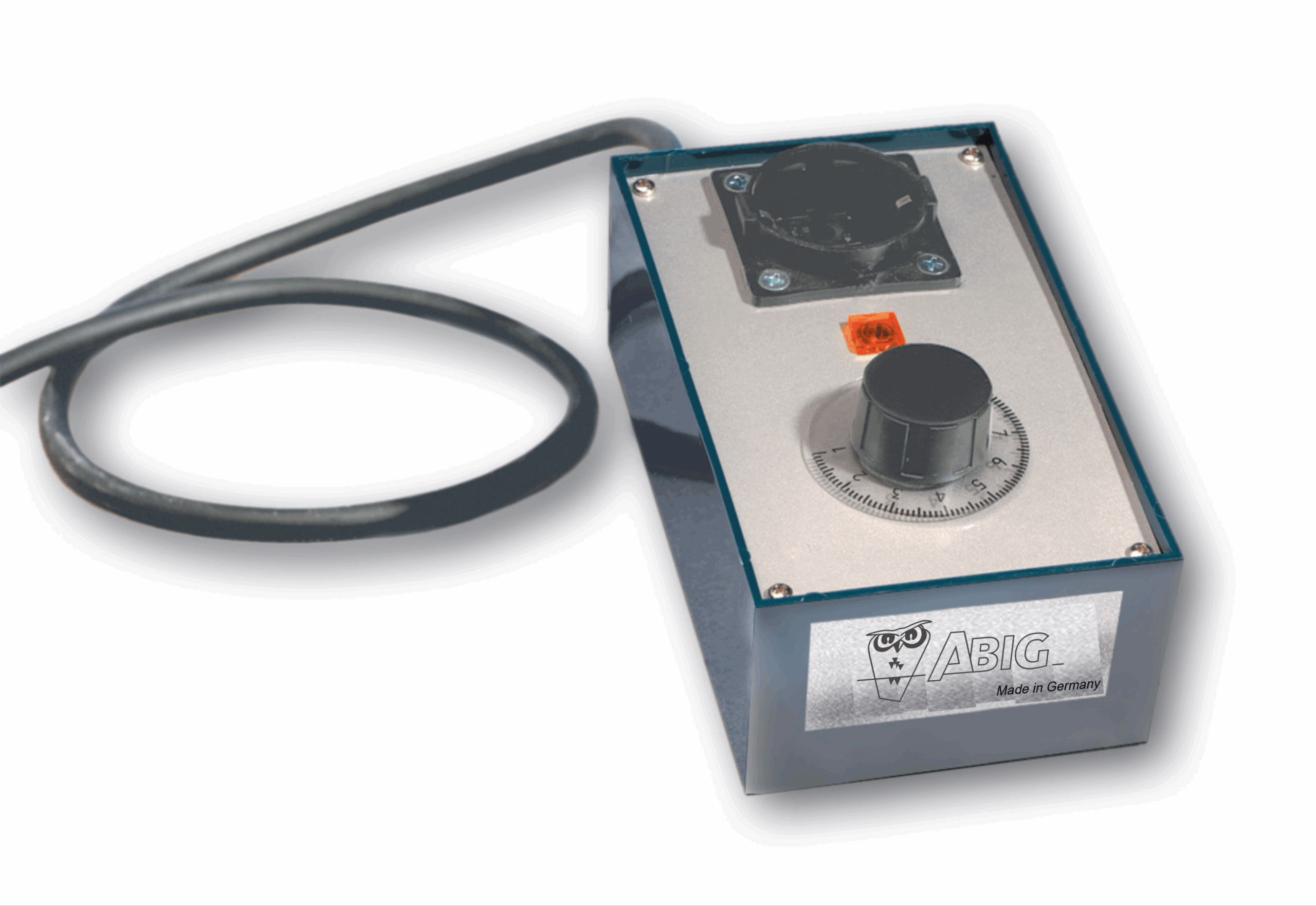

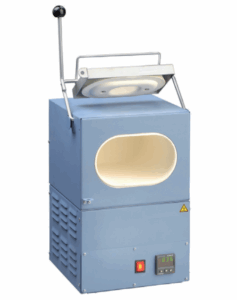

ABIG Kiln 110

Art. No.: 70100

- Heated all around

- Combustion chamber: 1.1 l

- Maximum temperature: approx. 1.000° C

- Connected load: 230 V~, 900 W, 4 A

- External dimensions H x W x D: 210 x 200 x 250 mm

- Combustion chamber H x W x D: 70 x 120 x 130 mm

- Net weight: approx. 5.8 kg

An all-round heated muffle kiln. The ABIG 110 is the ideal entry-level kiln. Fast heating and a large viewing window are further features that enamelers and jewelry designers appreciate. Heat output approx. 900°C after 30 minutes.

IMPORTANT: The “ABIG 110” kiln must not be operated without temperature control!

ABIG Kiln 135

Art. No.: 70110

- Heated all around

- Combustion chamber: 1.95 l

- Maximum temperature: approx. 1.200° C

- Connected load: 230 V~, 1200 W, 6 A

- External dimensions H x W x D: 250 x 260 x 300 mm

- Combustion chamber H x W x D: 90 x 140 x 155 mm

- Net weight: approx. 6,3 kg

The powerful ABIG 135 muffle kiln with all-round heating in a compact design is equipped with a thermal insulation panel in the swing door. The high heating capacity of the device allows all firing techniques to be carried out in the firing range from 400°C to 1.100°C, as well as glass, enamel, and ceramic firing, and the annealing and hardening of metals and tools.

IMPORTANT: The “ABIG 135” kiln must not be operated without temperature control!

ABIG Kiln 135 TH

Art. No.: 70111

- Heated all around

- Combustion chamber: 1.95 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~/1,200 W, 6A

- External dimensions H x W x D: 365 x 245 x 270 mm

- Combustion chamber H x W x D: 90 x 140 x 155 mm

- Net weight: approx. 11 kg

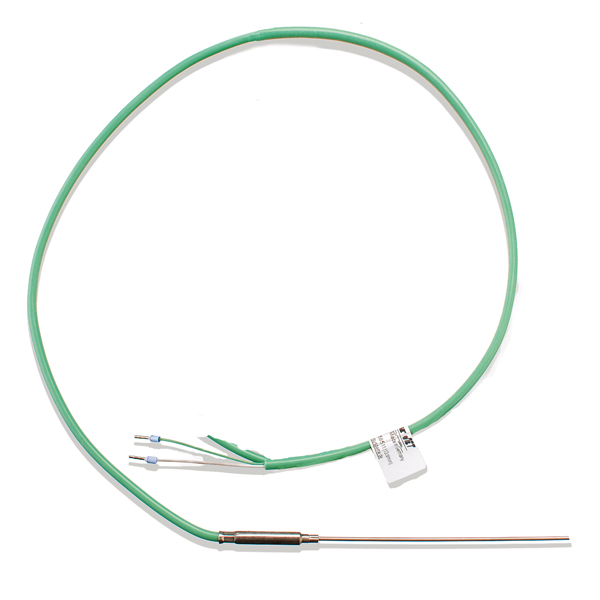

- Thermal element: 160 mm NiCr-Ni with diode plug

Area of application:

The kiln is suitable for all firing techniques in the firing range from 400°C to 1.100°C, e.g., glass, enamel, and ceramic firing, as well as annealing and hardening metals and tools. Without a fume hood, the kiln is not suitable for incinerating organic materials.

Scope of delivery:

Kiln with temperature control and temperature sensor.

ABIG Kiln 135 TH-A

Art. No.: 70112

- Heated all around

- Combustion chamber: 1.95 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~/1,200 W, 6A

- External dimensions H x W x D: 365 x 245 x 270 mm

- Combustion chamber H x W x D: 90 x 140 x 155 mm

- Net weight: approx. 11 kg

- Thermal element: 160 mm NiCr-Ni with diode plug

Area of application:

The kiln is suitable for all firing techniques in the firing range from 400°C to 1.100°C, e.g., glass, enamel, and ceramic firing, as well as annealing and hardening metals and tools. The kiln is suitable for incinerating organic materials.

Scope of delivery:

Kiln with temperature control and temperature sensor.

ABIG Kiln 150

Art. No.: 70120

- Heated all around

- Combustion chamber: 2,45 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~, 1.200 W, 6 A

- External dimensions H x W x D: 300 x 260 x 375 mm

- Combustion chamber H x W x D: 85 x 160 x 195 mm

- Net weight: ca. 8,0 kg

The powerful ABIG 150 muffle kiln with all-round heating in a compact design is equipped with a thermal insulation panel in the swing door. The high heating capacity of the device enables all firing techniques to be carried out in the firing range from 400°C to 1.100°C, as well as glass, enamel, and ceramic firing, and the annealing and hardening of metals and tools.

IMPORTANT: The “ABIG 150” kiln must not be operated without temperature control!

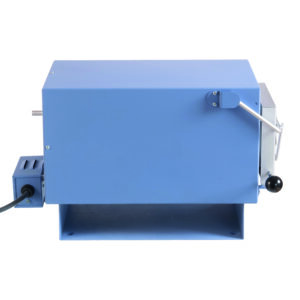

ABIG Kiln 180

Art. No.: 70130

- Heated all around

- Combustion chamber: 4,65 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~, 2.000 W, 10 A

- External dimensions H x W x D: 320 x 300 x 410 mm

- Combustion chamber H x W x D: 115 x 190 x 225 mm

- Net weight: approx. 14,1 kg

The powerful ABIG 180 muffle kiln with all-round heating in a compact design is equipped with a thermal insulation panel in the swing door. The high heating capacity of the device enables all firing techniques to be carried out in the firing range from 400°C to 1.100°C, as well as glass, enamel, and ceramic firing, and the annealing and hardening of metals and tools.

IMPORTANT: The “ABIG 180” kiln must not be operated without temperature control!

ABIG Kiln 180L

Art. No.: 70131

- Heated all around

- Combustion chamber: 7,00 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~, 2.500 W, 10 A

- External dimensions H x W x D: 320 x 300 x 540 mm

- Combustion chamber H x W x D: 115 x 190 x 340 mm

- Net weight: approx. 18,5 kg

The powerful ABIG 180 L muffle kiln with all-round heating in a compact design is equipped with a heat insulation panel in the swing door and heat-resistant metal paint.

The high heating capacity of the device enables all firing techniques to be carried out in the firing range from 400°C to 1.100°C, as well as glass, enamel, and ceramic firing, and the annealing and hardening of metals and tools.

IMPORTANT: The “ABIG 180 L” kiln must not be operated without temperature control!

ABIG Kiln 180 TH

Art. No.: 70132

- Heated all around

- Combustion chamber: 4,65 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~/2.000 W, 9A

- External dimensions H x W x D: 370 x 270 x 400 mm

- Combustion chamber H x W x D: 115 x 190 x 225 mm

- Net weight: approx. 16 kg

- Thermal element: 160mm NiCr-Ni with diode plug

Area of application:

The kiln is suitable for all firing techniques in the firing range from 400°C to 1.100°C, e.g., glass, enamel, and ceramic firing, as well as annealing and hardening metals and tools. Without a flue, the furnace is not suitable for incinerating organic materials.

Scope of delivery:

Kiln with temperature control and temperature sensor.

ABIG Kiln 180 TH-A

Art. No.: 70133

- Heated all around

- Combustion chamber: 4,65 l

- Maximum temperature: approx. 1.100° C

- Connected load: 230 V~/2000 W, 9A

- External dimensions H x W x D: 370 x 270 x 400 mm

- Combustion chamber H x W x D: 115 x 190 x 225 mm

- Net weight: ca. 16 kg

- Thermal element: 160mm NiCr-Ni with diode plug

Area of application:

The kiln is suitable for all firing techniques in the firing range from 400°C to 1.100°C, e.g., glass, enamel, and ceramic firing, as well as annealing and hardening metals and tools. With a fume extraction system, the kilnis suitable for incinerating organic materials.

Scope of delivery:

Kiln with temperature control and temperature sensor.

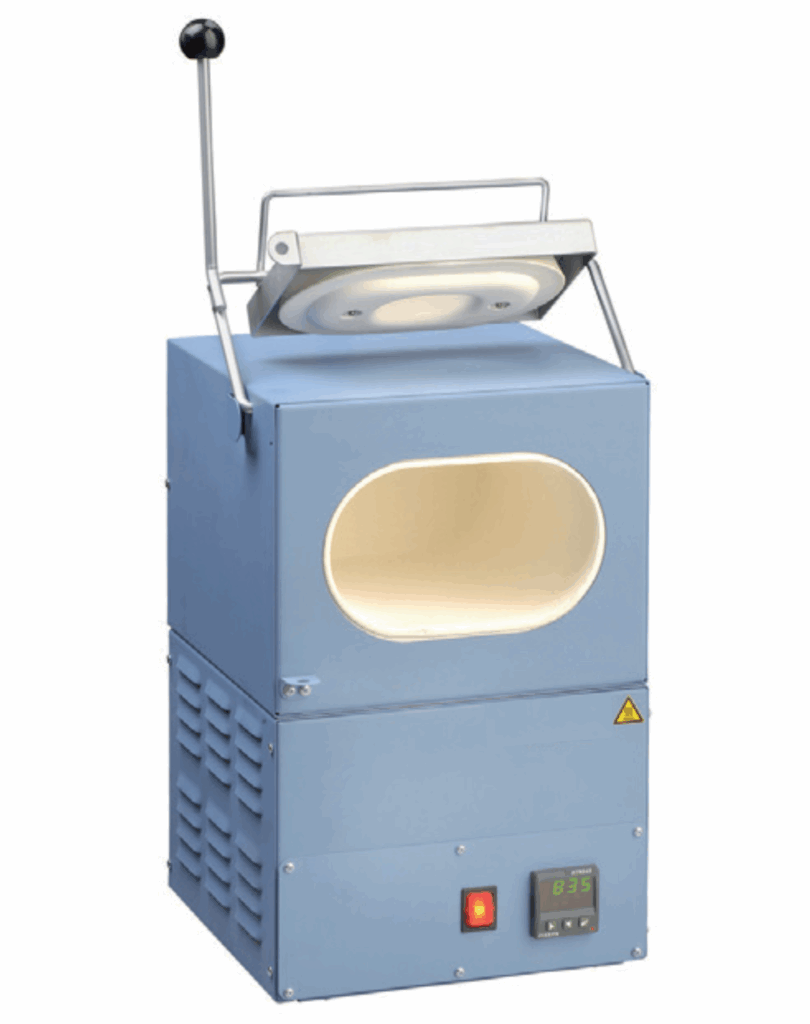

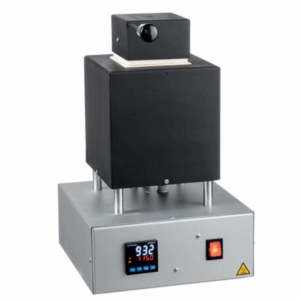

ABIG Kiln AM2

Art. No.: 70200

- Maximum temperature: approx. 1.200° C

- Connected load: 230 V~/1.000 W, 6A

- External dimensions H x W x D: 410 x 250 x 250 mm

- crucible measurement ∅ 55 x H 120 mm, hanging crucible

- Net weight: approx. 4,10 kg

Area of application:

The “AM2” crucible melting kiln is a kilnfor automatic melting operation at a constant temperature. It is ideal for melting small quantities of metal in industry and workshops. The device is ready for operation and heated up within a very short time.

The maximum operating temperature is 1.200°C. The temperature is automatically and constantly maintained at the set value.

Scope of delivery:

Kiln with temperature control, temperature sensor and deduction.